Whether you are an engineer, procurement specialist, salesperson, project manager, worker, contractor, or investor/owner, having a solid understanding of structural steel fabrication will make your project operations significantly smoother and more efficient.

Therefore, take just 5 minutes to read the entire article below; it will bring long-term benefits when you execute any structural steel construction project.

WHAT IS STRUCTURAL STEEL?

Structural steel is a type of high-strength steel designed to withstand heavy loads, making it widely used in construction for buildings, bridges, highways, and prefabricated steel structures. It is primarily composed of iron, carbon, and various alloys, and commonly appears in forms such as steel beams, steel columns, steel channels, steel angles, steel trusses, and steel plates.

Structural steel is known for its advantages including high durability, exceptional load- bearing capacity, flexible design options, fast fabrication time, and cost optimization. However, it also has disadvantages such as susceptibility to corrosion and rusting, loss of strength when exposed to high temperatures for extended periods, and the need for regular maintenance.

DETAILED STRUCTURAL STEEL FABRICATION PROCESS

Structural steel fabrication is the process of transforming raw steel into finished steel components (beams, columns, trusses, etc.) ready for assembly to complete the construction project.

-

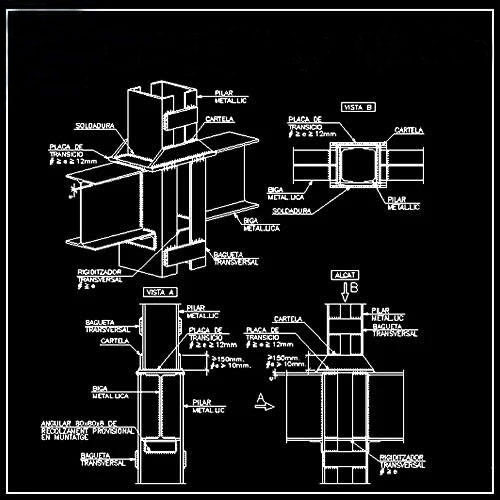

Design

Based on project requirements, structural engineers create structural drawings using specialized software such as AutoCAD, Revit, Tekla, or SAP2000. These drawings are then passed to steel detailers to develop detailed structural designs and 3D models, resulting in shop drawings, erection drawings, and material lists.

-

Cutting

After determining the required materials and completing procurement, the raw steel is inspected for quality before proceeding to cutting, drilling, and bending according to the drawings. Steel is cut precisely and drilled with necessary holes as per the drawings. This stage commonly uses methods such as thermal cutting, waterjet cutting, mechanical cutting, and primarily automated CNC machines to ensure absolute accuracy.

-

Drilling / Punching / Forming / Shaping

The drilling and punching stages are performed to create precise holes for installing bolts or rivets, enabling the connection of steel components. Subsequently, the steel undergoes forming and shaping stages to create curved angles or complex shapes that match the drawings exactly. Common methods include press brake bending, roll bending/section bending, or plate bending.

-

Welding & Assembly

Welding is the primary method for securely connecting steel components. Common welding methods for structural steel include Shielded Metal Arc Welding (SMAW), Gas Metal Arc Welding (GMAW), Flux-Cored Arc Welding (FCAW), and Submerged Arc Welding

(SAW).

Assembly is carried out after or concurrently with welding, where steel components arepreliminarily assembled into larger structural units.

-

Surface Treatment

This is a critical step to ensure even paint coverage and influence the lifespan of the coating. No matter how good the paint is, if the surface is not thoroughly treated, it is prone to peeling and rusting. Structural steel undergoes surface treatment using methods such as shot blasting or grit blasting to completely remove oil, grease, rust, weld slag, and create a rough surface for better paint adhesion.

In addition, other methods may be applied, such as Hand Tool Cleaning for small areas/repairs, Solvent Cleaning to remove oil and grease before painting, or Waterjetting for sensitive environments.

-

Painting/Coating

A multi-layer paint system is applied using methods such as electrostatic spraying, rolling, or brushing to ensure the required paint thickness. According to the process, the primer must be applied immediately after shot blasting, followed by subsequent layers once the specified drying time is achieved. DFT (Dry Film Thickness) is checked using a magnetic gauge, adhesion is tested, and visual inspection is performed. The entire painting process must be carried out in a controlled environment, with temperatures between 5–40°C, humidity <85%, and dust-free conditions.

-

Quality Control

Quality inspection is conducted throughout the fabrication process, primarily after each stage, including:

– Incoming inspection: Material certificates, dimensions, chemical composition, etc.

– In-process inspection: Checking steel after cutting, before and after welding, weld inspection (Visual Testing, Magnetic Particle Testing, Penetrant Testing, Ultrasonic Testing, Radiographic Testing).

– Coating inspection: Checking paint thickness, adhesion, and surface cleanliness after shot blasting.

– Final inspection: Checking straightness, surface and coating condition, load testing, or third-party approval if required by the project.

CHOOSING SUITABLE STRUCTURAL STEEL FABRICATION SERVICES

The quality of the structural steel fabrication process depends not only on fulfilling the above stages well but also on the structural steel fabricator who directly participates in the fabrication. Therefore, selecting a reputable steel fabricator greatly impacts the overall efficiency of your project.

As a structural steel fabricator with over 18 years of hands-on experience across hundreds of projects worldwide, Newinds understands that even the smallest error in the fabrication process can affect project performance, brand reputation, and above all, everyone’s safety. Therefore, in every small stage, we strive to execute meticulously, with detailed supervision to minimize errors as much as possible, and provide comprehensive reporting documentation so you can easily track the fabrication progress and detect any emerging issues early if they occur.

If you looking for a structural steel fabricator, offering tailored metal solutions that meet international standards.

Contact Newinds:

Email: sales@newindscorp.com

Phone/Whatsapp/Zalo: Ann Yen +84 868 482 038