To choose a high-quality CNC machining service in Australia, you should at least understand the basics of CNC machining, common techniques, and the quality standards of CNC machining manufacturers. Check out the article below to find the right machining provider for your project needs.

OVERVIEW OF CNC MACHINING SERVICE

This is a versatile process that fabricates parts from a range of materials, including metal, plastic, wood, and composites. CNC machines perform various manufacturing operations, such as CNC drilling, CNC milling, CNC turning, CNC EDM cutting, CNC gear hobbing, and CNC grinding.

These machines deliver rapid and reliable production with exceptional accuracy and precision. Moreover, they can shape intricate geometries that would be challenging or impractical to achieve manually.

In the world of manufacturing and engineering, the journey from raw materials to finished products involves intricate processes and precision. Industries ranging from aerospace and automotive to medical and electronics demand high-quality components that meet strict specifications.

Let’s explore the key stages of CNC machining techniques:

-

Material Selection and Preparation

Newinds carefully selects raw materials based on project requirements. Whether it’s steel, aluminum, or exotic alloys, the choice impacts the final product’s strength, durability, and performance.

Raw materials undergo rigorous quality checks, including chemical composition analysis and mechanical testing.

-

CNC Machining Techniques

The CNC machining service at Newinds utilizes various techniques, such as CNC milling, turning, drilling, and grinding. These processes shape raw materials into precise steel components. Skilled machinists use computer-controlled equipment to achieve tight tolerances and smooth finishes.

-

Cutting and Forming

Laser cutting, waterjet cutting, and plasma cutting are used to create intricate shapes from sheets or bars. Bending, rolling, and stamping form the material into desired geometries.

-

Surface Treatment

Surface finishes enhance aesthetics and protect against corrosion. Newinds offers options like powder coating, anodizing, and electroplating. Deburring and polishing ensure smooth edges and eliminate sharp burrs.

-

Assembly and Quality Control

Components are assembled into subassemblies or complete machining parts. Welding, fastening, and adhesive bonding play a crucial role.

Stringent quality control checks verify dimensions, tolerances, and functionality.

-

Final Inspection and Packaging

Newinds inspects each machined product meticulously. Measurements, hardness tests, and visual inspections confirm compliance with specifications. Proper packaging ensures safe transit and delivery to customers.

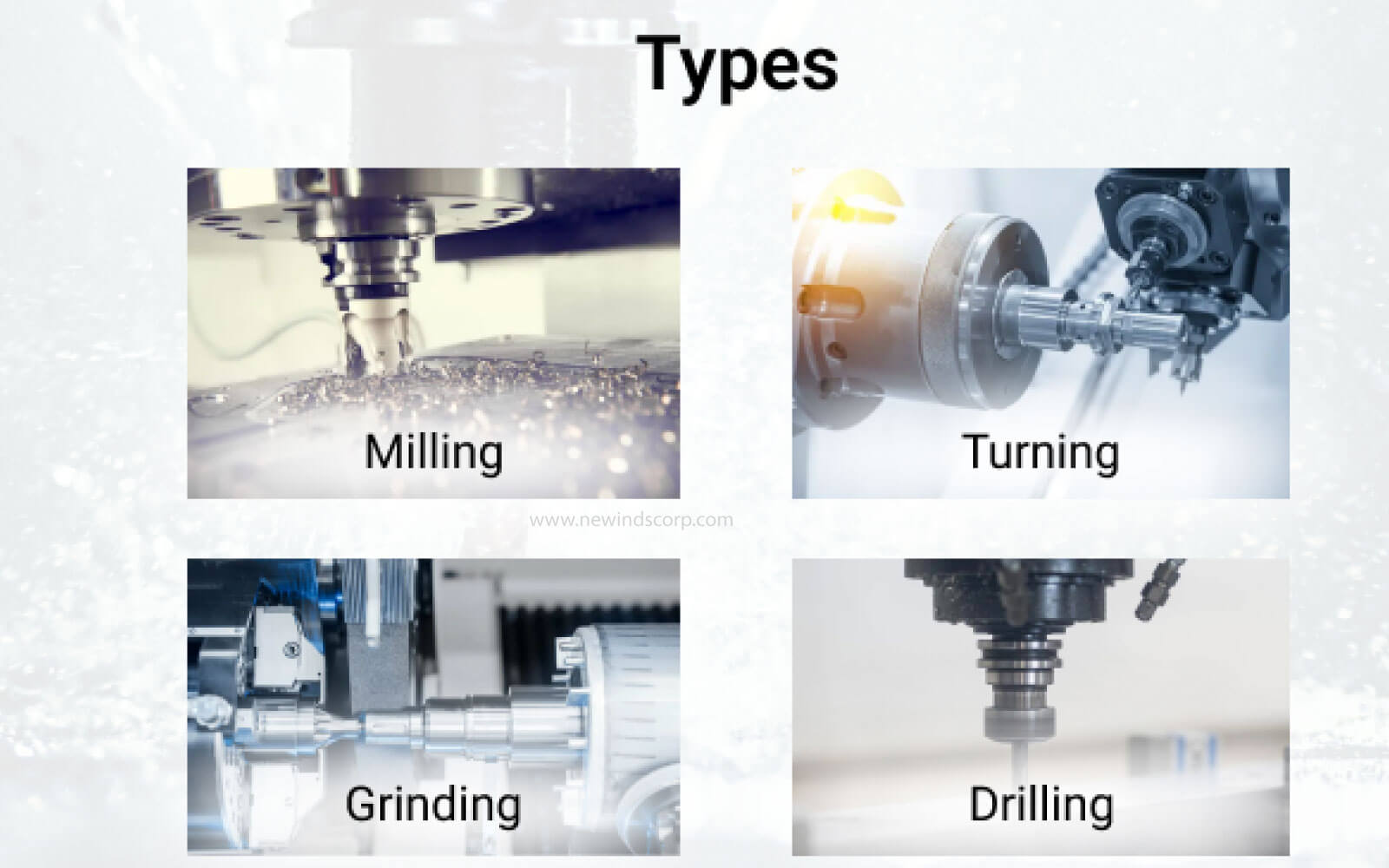

COMMON TYPES OF CNC MACHINING TECHNIQUES

Based on the tools used, operating principles, materials, and specific applications of each product, CNC machining is classified into the following types:

- CNC Milling: Suitable for complex parts, flat surfaces, grooves, holes, and threads.

- CNC Turning: Used for machining shafts, tubes, bearings, and gears.

- CNC Drilling: Creates precise holes for bolts, screws, and pipelines.

- CNC Grinding: Enhances surface smoothness and achieves extremely tight tolerances, commonly used in precision engineering.

- CNC Electrical Discharge Machining (EDM): Processes hard metals such as titanium, tungsten carbide, and molds.

Therefore, you need to carefully analyze these factors and the type of product required for your project to choose the right type of CNC machining service. Alternatively, you can simply contact a reliable CNC machining manufacturer in Australia, who can offer expert consultation and supply the most suitable machining parts for your needs.

CHOOSE A TRUSTED CNC MACHINING MANUFACTURER IN AUSTRALIA

Newinds Corp from Vietnam, an expert metal fabrication company, specializes in transforming raw materials into high-quality machined products. e offer custom CNC Machining service delivery to Sydney, Melbourne, Brisbane, Perth, Adelaide, and other locations in Australia.

The machined products will be supplied directly from our factory in Vietnam to you, wherever you are in Australia. With custom manufacturing capabilities, Newinds is dedicated to delivering precision components tailored to your unique requirements. Whether you need a single prototype or a large production run, our flexible approach means there are no minimum or maximum quantity requirements. Our commitment to quality and innovation is unwavering, making us the best choice for your machining needs.

Newinds’ commitment to excellence – from raw materials to finished machined products – ensures that clients receive reliable, top-tier components for their applications.

If you are looking for a high-quality CNC machining manufacturer in Australia offering tailored metal solutions that meet international standards.

Contact Newinds:

- Email: sales@newindscorp.com

Phone/Whatsapp/Zalo: Ann Yen +84 868 482 038