Machining parts are widely used across various industries in Australia, from mining and aerospace to medical sectors. All parts are designed and machined according to strict standards to ensure excellent load-bearing capacity and durability. Therefore, selecting a reputable machining part manufacturer is the most critical factor in obtaining high-quality products.

WHAT ARE MACHINING PARTS?

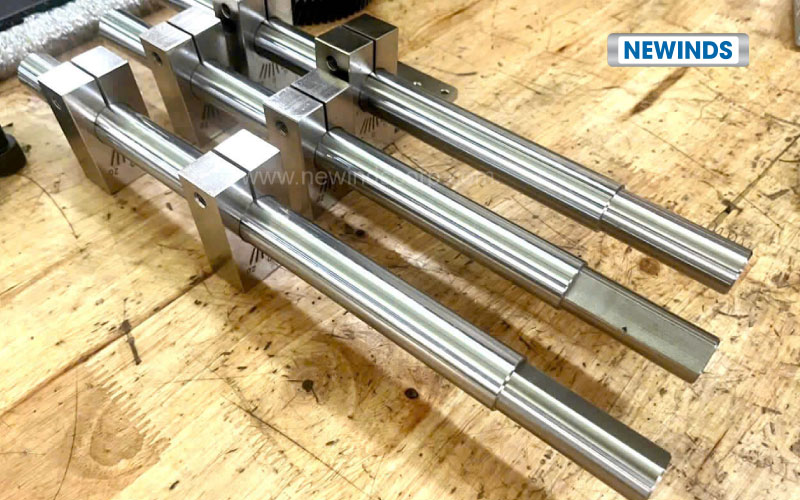

Machining parts are components created through the process of removing material from a raw workpiece to achieve precise dimensions and specific shapes using CNC machines such as turning, milling, drilling, grinding, and more.

Key Characteristics:

- High precision

- Minimal tolerance deviation

- Ability to produce complex shapes and sizes

- Excellent surface finish

Common Materials

- Carbon steel and alloy steel

- Stainless steel

- Aluminum

- Copper and brass

- Engineering plastics (POM, Nylon, ABS, etc.)

MACHINING PARTS MANUFACTURING PROCESS

The production process for machining parts is optimized from design to final quality inspection. First, the product model is designed in 3D using software such as SolidWorks or AutoCAD. The next step is selecting the appropriate material based on project requirements.

Main Machining Steps Include:

– CNC Turning: Rotational machining to create cylindrical shapes, shafts, or valves. CNC automation ensures high precision.

– CNC Milling: Milling to produce grooves, holes, or complex surfaces, commonly used for automotive body panels.

– Grinding & Finishing: Polishing to achieve a smooth surface, especially important for medical machined parts.

– Welding & Assembly: Welding and assembly (if required), in accordance with AS/NZS 1554 standards.

– Quality Inspection: Utilizing NDT (Non-Destructive Testing), laser measurement, and pressure testing.

APPLICATIONS

- Shafts, gears, bushings

- Frames, brackets, CNC-machined plates

- Connectors and transmission components

- Replacement parts for industrial machinery

TOP MACHINING PART MANUFACTURERS IN VIETNAM

- ABC Machining Manufacturing

- Newinds Corporation

- VPIC Group

- Viet Nhat Tan Precision Mechanical Co., Ltd

- VietNamCNC / Precision Technology Co., Ltd

KEY FACTORS WHEN CHOOSING A MACHINING PART MANUFACTURER IN VIETNAM

-

Technical Capability

This is the most important factor in determining whether a supplier has sufficient machining capacity.

– Types of machining parts they can produce (simple/complex/high-precision)

– Machinery: CNC milling (3-axis, 4-axis, 5-axis), CNC turning / Swiss-type, EDM, grinding (if available)

– Minimum achievable tolerance

– Minimum part size capability

– Ability to handle prototypes and mass production

-

Quality Control System

Reputable suppliers are always willing to provide details of their quality control system. If there is no clear QC process, eliminate them immediately.

Mandatory elements:

– Quality certifications

– Measuring equipment: CMM, Micrometer, Height Gauge

– Clear procedures: Incoming inspection, In-process inspection, Final inspection

– Documentation: Inspection reports, material certificates, etc.

-

Experience with International Projects and Export

Check whether the supplier has previously manufactured for international clients and exported products. This factor evaluates their ability to understand English technical drawings, communicate via technical emails, comply with international standards, and handle export experience.

-

Ability to Read and Interpret Technical Drawings

In reality, many machining part manufacturers in Vietnam have excellent machining skills but lack the ability to read technical drawings properly. This limits their access to many international clients. Therefore, carefully verify this capability through:

– Do their engineers and project managers understand technical drawings?

– Do they provide design feedback?

– Are they proactive in identifying design errors and suggesting improvements?

-

Pricing and Cost Structure

Reasonable pricing is a plus, but it is not the deciding factor. You should analyze whether the quotation is detailed, stable over time, and compare it with other suppliers.

Currently, the number of machining part manufacturers in Vietnam is quite large, with a strong concentration in industrial zones near the two major cities: Ho Chi Minh City (Dong Nai, Binh Duong, Long An, Ba Ria – Vung Tau) and Hanoi (Bac Ninh, Hung Yen, Hai Phong).

If you are looking for a reliable solution for precision machining parts that are durable and meet high standards, Newinds is a trustworthy supplier for your project.

Contact Newinds today to discuss your requirements

Email: sales@newindscorp.com

Phone/Whatsapp: +84 868 482 038