As demand for durable and cost-effective building solutions continues to rise, steel roof trusses have become a preferred choice in residential and commercial construction across Australia. This article provides Australian buyers with practical insights into steel truss systems and guidance on finding a reliable supplier.

WHAT IS A STEEL ROOF TRUSS SYSTEM?

A steel roof truss is a triangular framework made of straight steel members that are connected at joints through welding or bolting. This configuration helps distribute vertical, horizontal, and inclined loads evenly across the structure.

Comprising chords, struts, and ties, steel trusses act as the main support for roofs, bridges, and industrial or commercial buildings. In addition, it is highly valued for its strength, stability, and material efficiency.

WHAT ARE THE MAIN TYPES OF STEEL TRUSSES?

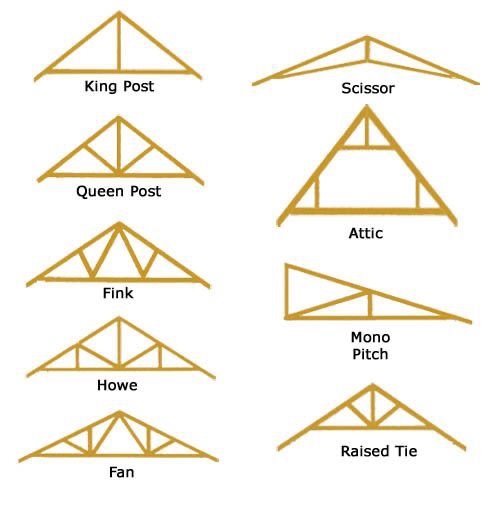

Steel trusses come in a variety of configurations to suit different spans, loads, and design requirements. Below are the most common types of steel trusses used in construction in Australia.

-

King Post Truss

A simple triangular truss with a single vertical post connecting the ridge to the base. This type is commonly used for short-span roofs such as garages, sheds, and small home extensions.

-

Queen Post Truss

Two vertical posts divide the span into equal parts, creating a balanced and more stable framework. The design is often applied in medium-span residential or light commercial roofs.

-

Fink Truss

With its characteristic “W” shape, the Fink truss combines strength with material efficiency. This steel roof truss is widely used in residential, commercial, and light industrial buildings.

-

Howe Truss

Diagonal compression and vertical tension members form a compact triangular structure that efficiently carries heavy loads. This truss is suitable for factories, warehouses, and other large-span constructions.

-

Fan Truss

Narrow struts radiate from the top joint, giving the frame a fan-like appearance that distributes loads evenly. The fan truss is common in wide-span industrial projects where stability and uniform load transfer are required.

-

Scissor Truss

Intersecting bottom chords form a vaulted ceiling that provides both height and openness. This design is frequently used in churches, halls, and modern architectural buildings.

-

Mono pitch Truss

A single sloping chord defines the roof’s angle, creating a clean and modern appearance. The mono-pitch truss is commonly used in lean-tos, extensions, and small industrial facilities.

-

Raised Tie Truss

A raised tie beam increases headroom beneath the roof while maintaining overall stability. This truss type is suitable for attic conversions or loft-style spaces that require additional height.

PROS AND CONS OF STEEL ROOF TRUSS

Steel roof truss systems are widely recognized for their reliability, precision, and versatility in construction. Below is an overview of their main Pros and Cons:

Pros

- High structural strength: Ensures excellent load-bearing capacity and long-term stability for both residential and commercial roofs.

- Quick and efficient installation: Prefabricated components simplify on-site assembly, reducing construction time and labor costs.

- Durability across all climates: Resistant to corrosion, pests, and moisture, making it suitable for Australia’s coastal and humid regions.

- Lightweight yet stable: Minimizes the overall structural load while maintaining rigidity and balance.

- Flexible design options: Easily adapts to different roof shapes, spans, and architectural layouts.

- Minimal maintenance: Requires fewer inspections than timber trusses, with a long service life when properly coated.

- Sustainable and recyclable: Steel is a fully recyclable material that supports green building initiatives and energy-efficient design.

Cons

- Higher upfront cost: The initial investment may be greater than timber alternatives.

- Corrosion protection: Coatings such as galvanizing are required to prevent surface degradation over time.

- Thermal insulation: Additional insulation may be necessary to optimize energy performance in hot or humid environments.

- Transportation and handling: Large prefabricated components should be carefully coordinated during delivery and installation.

COMPLIANCE AND QUALITY STANDARDS FOR STEEL ROOF TRUSSES IN AUSTRALIA

All steel roof trusses used in Australia must comply with national building regulations and recognized standards to ensure safety, structural integrity, and long-term durability.

Manufacturers and suppliers commonly adhere to:

- AS/NZS 4600

- AS/NZS 1170

- AS/NZS 1397

Partnering with certified fabricators ensures that your truss system not only meets design expectations but also complies with local council requirements and Australian building codes.

CHOOSE A STEEL ROOF TRUSSES FABRICATOR FROM VIETNAM

Newinds Corp provides steel roof truss fabrication services from Vietnam, offering a wide range of custom truss types tailored to each client’s specifications.

With a skilled and experienced engineering team, we deliver high-quality and cost-effective solutions that fully comply with international standards, including AS/NZS, ASTM and EN, ensuring strength, precision, and long-term reliability for every project.

If you are looking for a trusted steel truss fabricator, we welcome the opportunity to discuss your needs.

Contact Newinds today to discuss your requirements

- Email: sales@newindscorp.com

- Phone/Whatsapp: +84 868 482 038